Top Aluminium Manufacturers in Turkey: The Ultimate Sourcing Guide

Table of Contents

The European supply chain is undergoing a tectonic shift. While imports from the Far East are becoming increasingly unattractive due to rising logistics costs and tariffs, the Turkish aluminium industry is moving into the spotlight for strategic buyers. This isn’t just about arbitrage or currency advantages anymoreit is about massive capacity expansion and technological specialization.

If you are looking to source in Turkey today, you need to distinguish the “Big Players” from the niche workshops. We have analyzed production data and investment reports from late 2025 to give you a clear, unfiltered market overview.

1. Assan Alüminyum: The European Foil Giant

When it comes to flat rolled products, there is no ignoring Assan Alüminyum. As a subsidiary of Kibar Holding, the company hasn’t just survived; it has thrived, climbing to rank 44 in the list of largest industrial companies in Turkey (ISO 500).

The Buyer’s Brief:

- Total Capacity: 360,000 tons per year (as of late 2025) across its Dilovası and Tuzla facilities.

- Specialization: With a foil production capacity of 130,000 tons, Assan is now one of the two largest foil manufacturers in all of Europe.

- Portfolio: Coils, sheets, foils, and pre painted products.

Curator’s Tip: This is the go-to partner for the packaging and construction industries requiring extremely high volumes. Visit Website

2. Asaş Alüminyum: The French Connection

Asaş Alüminyum is far more than just an extrusion plant. In 2025, the company massively expanded its global footprint through the strategic acquisition of Eurofoil France. Back at its home base in Akyazı (Sakarya), Asaş operates one of Europe’s largest integrated industrial parks.

- Infrastructure: 1,000,000 m² total area with 5 specialized production facilities (including profiles, composite panels, and PVC).

- Workforce: Staff count has surged to over 3,000.

- Relevance: Particularly strong in the automotive and railway sectors.

3. Eti Alüminyum: The Only Primary Producer

Here is a critical distinction for your supply chain resilience: While most other manufacturers remelt or process aluminium, Eti Alüminyum is the only producer in Turkey that extracts aluminium directly from bauxite (primary aluminium). This makes their Seydişehir plant strategically indispensable.

Liquid aluminium capacity stands at 82,000 tons, covering about 10% of Turkey’s domestic demand. Crucial for 2026: Eti is commissioning a new rolling mill with a 100,000-ton capacity, specifically targeted at the defense industry. This aligns with trends seen in Turkey’s foreign trade indices, which show a clear shift toward higher value export goods. Visit Website

4. Arslan Alüminyum: The Billet Specialist

If you are hunting for raw material (billets), you will often end up at Arslan Alüminyum. Following massive investments, the company has reached a theoretical casting capacity of 240,000 tons per year at its integrated facilities in Bilecik. While their long-term moonshot is one million tons, Arslan is already a heavyweight in foundry products, ranking 276th in the ISO 500. Visit Website

5. Şahinler Metal: The Market Leader for Secondary Aluminium

Sustainability is the keyword for 2026. Şahinler Metal dominates the market for secondary aluminium (recycling) in Turkey. With a production capacity exceeding 190,000 tons, they are not only a top exporter in the aluminium casting category but also a cost efficient option for companies looking to lower their carbon footprint through recycled materials. Much like the leading iron casting manufacturers in Turkey, the focus here is on modern reprocessing. Visit Website

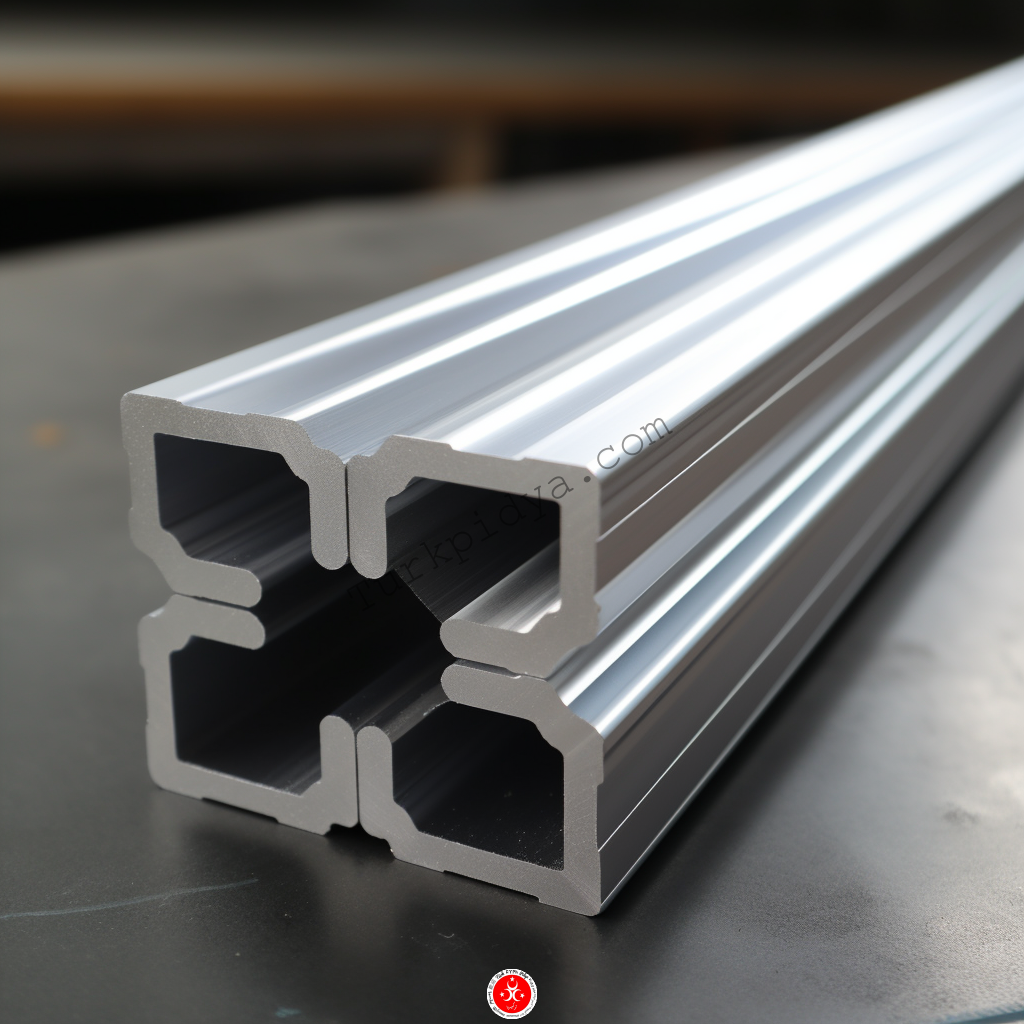

6. Sistem Alüminyum: Facade Systems and More

Sistem Alüminyum is laser focused on the construction industry. As a fully integrated manufacturer of architectural facade systems and composite panels, they are a frequent partner for large scale projects. Beyond architecture, their industrial profile division is seeing steady growth. Visit Website

7. Akpa Alüminyum: The Reliable Veteran

In the market since 1986, Akpa Alüminyum is a staple in the mid market segment. Serving both domestic and export markets with a wide range of profile systems, they are known as a reliable partner for standard applications. Visit Website

8. Alfa Metal: High-Tech Casting

Alfa Metal bets big on technology. They utilize the “Wagstaff AirSlip Hot Top Billet Casting System,” one of the most advanced casting methods globally. The result is exceptionally high metallurgical quality in their billets, making Alfa the top choice for demanding processors. Visit Website

9. Yavuz Alüminyum: 9,000 Tons of Monthly Power

The growth trajectory of Yavuz Alüminyum is remarkable. Through targeted investments in 50-ton melting furnaces and homogenization plants, their Hadımköy facility has boosted capacity to 9,000 tons per month. An interesting detail for insiders: The newly built factory in Çorlu was leased out, allowing the company to focus entirely on optimizing the main site. Visit Website

10. Vig Metal: The Magnesium Pioneers

Here we have a true specialist. Vig Metal isn’t your typical mass producer; they are a technology leader. They are known globally for producing 1500 mm wide magnesium sheets using the “Twin Roll” process. With a 5,000-ton magnesium casting capacity, they serve niches where every gram of weight saving counts. Visit Website

11. Erdoğanlar Alüminyum: The Hidden Champion

Often underestimated but highly professional, Erdoğanlar Alüminyum now employs nearly 780 people, including over 140 engineers and white collar staff. With over 30 years of experience and a strong R&D department, they position themselves as a partner for complex, bespoke solutions rather than just commodity goods. Visit Website

12. Cansan Alüminyum: Industrial Quality

Cansan has established itself as a reliable supplier for demanding sectors like automotive and rail systems. Their vertical integration and quality management systems are specifically designed to meet the rigorous standards of these industries. Visit Website

13. Astaş Alüminyum: Focused on Europe

Not to be confused with Asaş (see above), Astaş has been in the business since 1974. Their operations are heavily oriented toward exporting to key European markets, scoring high on experience and consistent supply chain reliability. Visit Website

14. Bor Billet Alüminyum: Raw Material Focus

As the name suggests, Bor Alüminyum‘s core competence lies in billet production. Since 1997, the company has transformed from ingot casting to a specialized billet producer, supplying many extrusion plants that lack their own foundry capabilities. Visit Website

15. Formal Alüminyum: Customer Centric Production

Backed by over four decades of partner experience, Formal Alüminyum is known for its agility in responding to customer requests. Their technical team is regarded as highly solution oriented, making Formal a great address for mid sized orders with specific requirements. Visit Website

16. Zahit Alüminyum: From Workshop to Factory

The story of Zahit Alüminyum is a classic Turkish success story: started in 1983 as a small workshop, today it is a fully integrated production facility. Since 1998, they have been extruding their own profiles, eliminating dependency on external suppliers. Visit Website

17. Almesan Alüminyum: The TwinBand Technology

Finally, a technological highlight: Almesan Alüminyum is the only company in Turkey possessing “TwinBand” casting technology. This allows for the precise production of 4xxx, 5xxx, and 6xxx series alloys with a capacity of 50,000 tons. Such specialized alloys are frequently in demand at the Sefine Shipyard and other heavy maritime industries.

The Bottom Line for Buyers

Turkey offers the right partner for every needfrom giants like Assan for massive volume to specialists like Vig Metal for lightweight engineering. Don’t just check the price tag; vet the technological fit of their facilities against your specific alloy requirements.